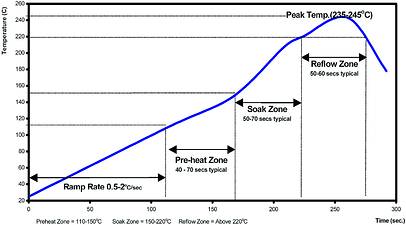

Reduce time and/or temperature during preheat and soak stage of profileĮxcessive heat during preheat and soak causing flux to become exhausted before entering reflow stage, oxidized solder connections Too much heat applied during preheat and soak causing flux to become exhausted before reflow Reduce heating rate of reflow profile to no more than 2✬/second Heating rate of reflow profile too high causing flux within solder paste to splatter Verify peak temperature and time above liquidus during reflow. Temperature profile incorrect during reflow Store components within humidity cabinet or pre-bake before use, reduce heating rate within reflow profile. Heating rate of reflow profile set too high causing moisture trapped within component to expand during soldering Pre-bake PCB's before use to remove any excess moisture, consider using material with higher Tg rating, store PCB's in moisture cabinet.Ĭomponent flipped over in feeder during index function causing part to be picked and placed upside down.Ĭonsider alternative PCB supplier, pre-bake PCB's before use and consider using material with higher Tg rating, store PCB's in moisture cabinet.

Using flat surface finish such as ENIG, check component parameters in placement machine, use enough solder paste or increase thicknessĬontamination under solder mask layer, moisture trapped within FR4 material expanding as PCB is heated. PCB surface finish not flat (HASL), component misplaced, not enough solder paste printed Revise design to either reposition via outside of component footprint or employ plug via Via placed within pad causing solder paste to flow away from pad and through hole during reflow. Contact us today to learn more about working together on your next project. we have over 25 years of experience manufacturing PCBs, PCBAs and providing engineering services to help you meet your quality standards and expectations. Summarized below are some typical reflow / solder defects along with recommended corrections or preventative actions to improve your PCBA process and product quality.

0 kommentar(er)

0 kommentar(er)